|

|

|

|

|

|

|

|  |

| |

Calculation of tensile strength of an additive

The strength of a polymer additive decides on the performance of the composit substance. The right tensile strength of the additive is important for the desired performance of the composite.

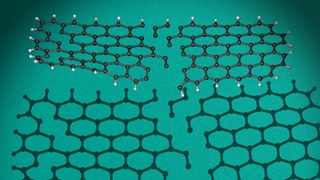

A nanoflake made from graphene, which can be viewed as diamond in two dimensions,

has been tensile tested until it breaks.

A nanoflake made from graphene, which can be viewed as diamond in two dimensions,

has been tensile tested until it breaks.

Pretty easy to recognise

is the honeycomb pattern made of carbon atoms, which behave as a nanoscale

trampoline.

The critial tensile strength, at which the break of the nanoflake occurs,

is determined and the shape of the flake is dimensioned such, that the desired

performance can be reached.

Not as a towel, the flake disrups not on its weakest point only, but bursts into several pieces.

Through the similar molecular construction the flake does not show a weak spot, but is identically strong everywhere.

The break point occur rather randomly by thermal fluctuations of the atoms, which are

contained within the dynamic simulation.

The production of graphene flakes in a certain dimension is complex and costly, the experimental analysis quite difficult. With the computer simulation the right dimension can be determined in advance and be demanded from production.

Calculation of material properties

Often desired material properties like viscosity, elasticity, thermal conductivity, diffusion or compressibility of substances and mixtures of substances can be ordered here and calculated from their chemical structures.| Feedback |